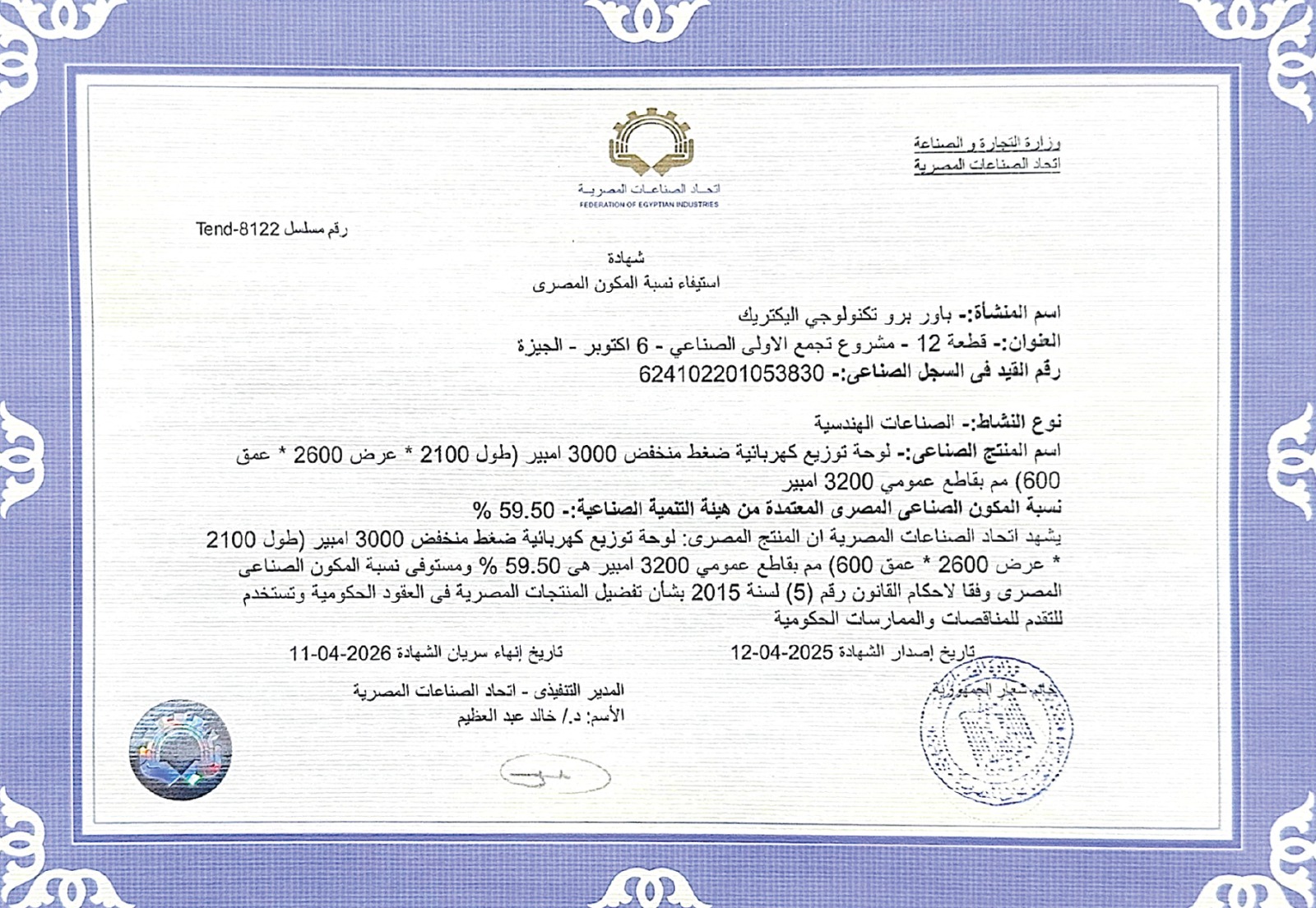

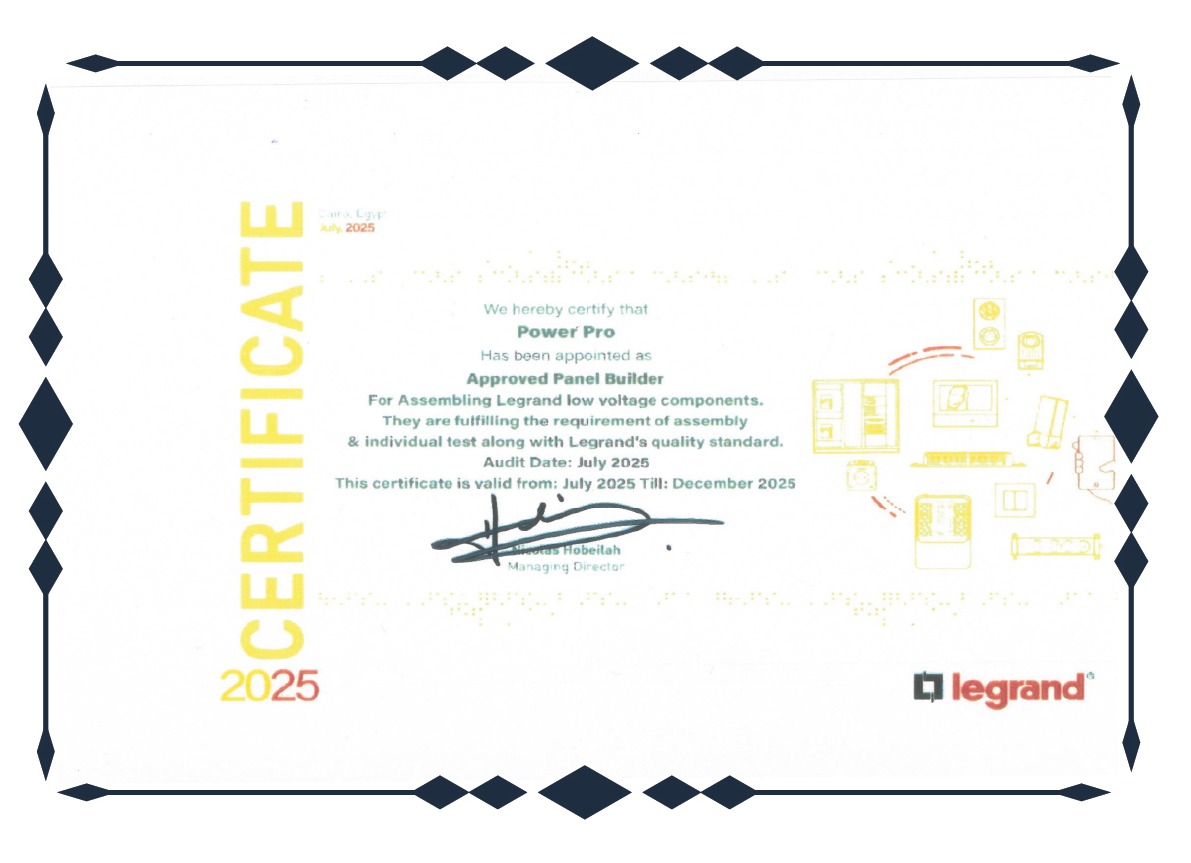

excels in the production of low-voltage panels, ensuring top-notch quality and reliability for safe electrical management

Power Pro Technology

Each panel undergoes a series of rigorous tests at the company's dedicated testing facility. Initial tests include continuity, insulation resistance and dielectric strength checks, ensuring all connections are correct and secure.

Our Service List

FOR LOW & MEDIUM VOLTAGE PANEL MAINTENANCE & INSTALLATIONS

Each panel undergoes a series of rigorous tests in the company's

dedicatorous tests i n the company's dedicated testing facility.

This systematic approach

reduces errors and enhances

the overall quality of the final

product.

+

Work Experience

About Us

Power Pro Technology Electric excels in the production of low-voltage panels, ensuring top-notch quality and reliability for safe electrical management.

Our expertise extends to the maintenance of low-voltage and medium voltage panels, where they employ advanced techniques and stringent safety protocols to guarantee optimal performance and longevity through Power pro Technology Electric service centre.

innovation and customer satisfaction

100%

Strong Commitment

With a strong commitment to innovation and customer satisfaction, Power Pro TechnologyManufacturing stands at the forefront of the electrical equipment industry

Delivering

delivering comprehensive solutions tailored to meet the diverse needs of its clients.

Why Choose Us

Developing a design that

is easy to use and

navigate

Innovation in Electrical Solutions Cutting-Edge Technology: Staying at the forefront of electrical technology, including advancements in low-voltage panels, busbar systems, and related machinery.

Tailored Solutions

QUALITY

Energy Efficiency

Impact International Presence

Research & Development

Regulatory Compliance

SERVICES CENTER

FOR LOW & MEDIUM VOLTAGE PANEL MAINTENANCE & INSTALLATIONS

Each panel undergoes a series of rigorous tests in the company's

dedicatorous tests i n the company's dedicated testing facility.

insulation resistance, and

dielectric strength, ensuring all connections are correct and secure.

Functional testing simulates real-world conditions to verify the

operation o f all circuits and components.

Initial tests include

checks for continuity,

any issues before

the panel is delivered t o the client.

PowerPro's comprehensive testing protocols ensure that each panel

per forms reliably under various conditions.

This phase is crucial

for identifying and rectifying

Power Pro Technology Electric is your end-to-end partner for medium

voltage (MV) solutions. W e supply, install, and commission high-quality

equipment designed t o deliver safe, reliable power in industrial,

commercial, and infrastructure projects.

Medium Voltage

Solutions

M V Switchgear:

Indoor and outdoor designs (up t o 24kV), metal-clad and modular

systems.

• Ring Main Units (RMU):

SF6, air-insulated, and solid dielectric types up t o 24kV.

Scope of Supply

& Installation

Oil-immersed and dry type transformers (100kVA-5,000kVA) up to 24kV.

Transformers:

electrical design, product selection, installation,

testing, and commissioning — in full compliance with international

standards such a s IEC and ANS

W e handle all stages:

Contact With Us

Let’s Work Together?

Providing legal advice, contract drafting, compliance assistance, intellectual property protection, and other legal support for businesses.

Have Any Question?

0108 050 0008 - 0155 225 5100 -0150 120 9120

Send Email

info@power-pro.tech

Contact Us

)

)

)

)